This rubber has excellent resistance to fuels and oils and is commonly used for making automotive gaskets and seals as well as gaskets for the marine sectors and seals for tanks and pipelines.

Nitrile rubber sheet properties.

Nitrile is the most commonly used rubber material.

The pursuit of developing a new synthetic oil resistant rubber became imperative with the rapid industrialization of the western hemisphere.

It has moderate aging properties and good adhesion to metal.

Before nitrile sheet rubber was developed manufacturers had to make do with natural rubber the supply and performance of which were erratic.

Nbr b200000 rubber is a copolymer of butadiene and acrylonitrile.

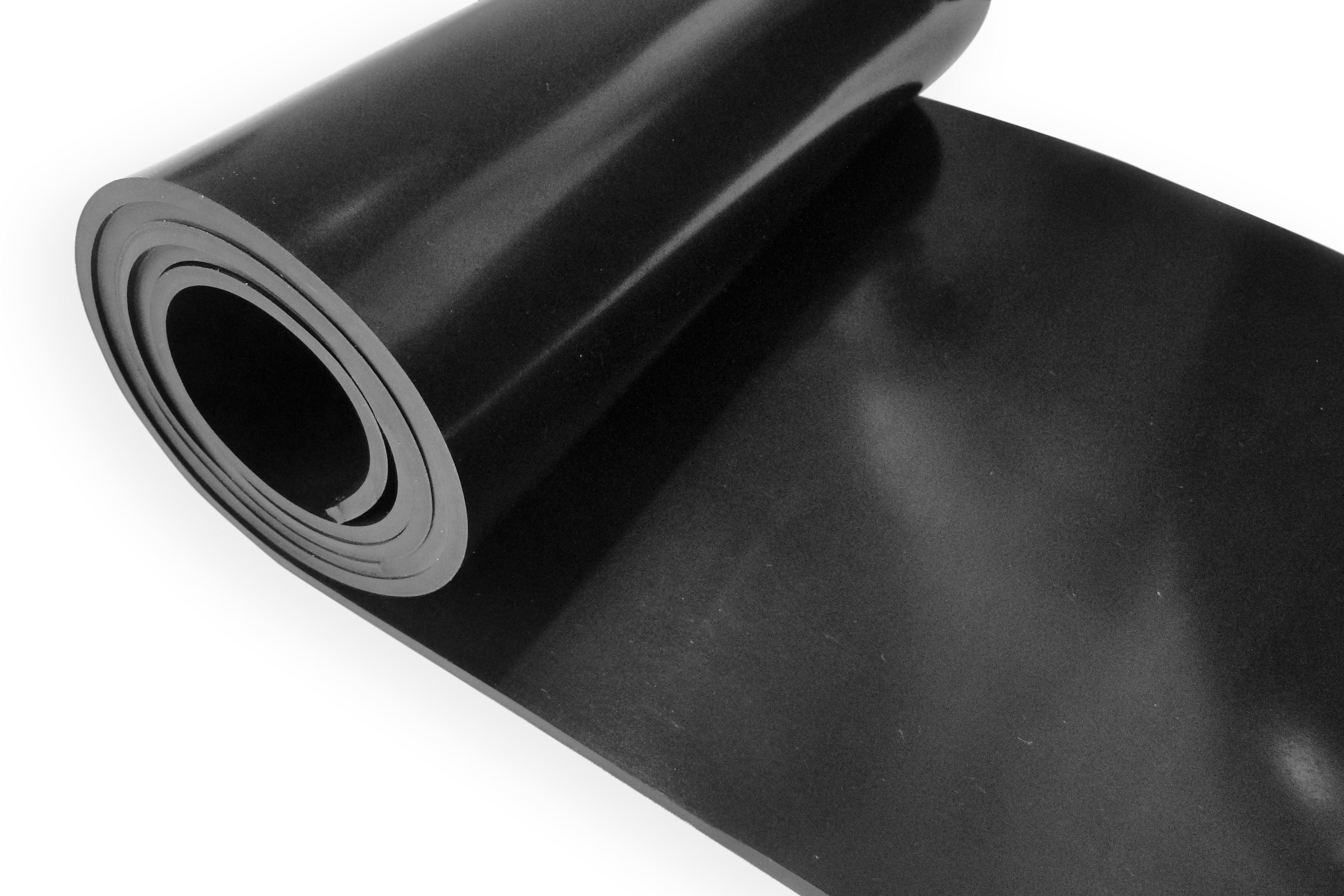

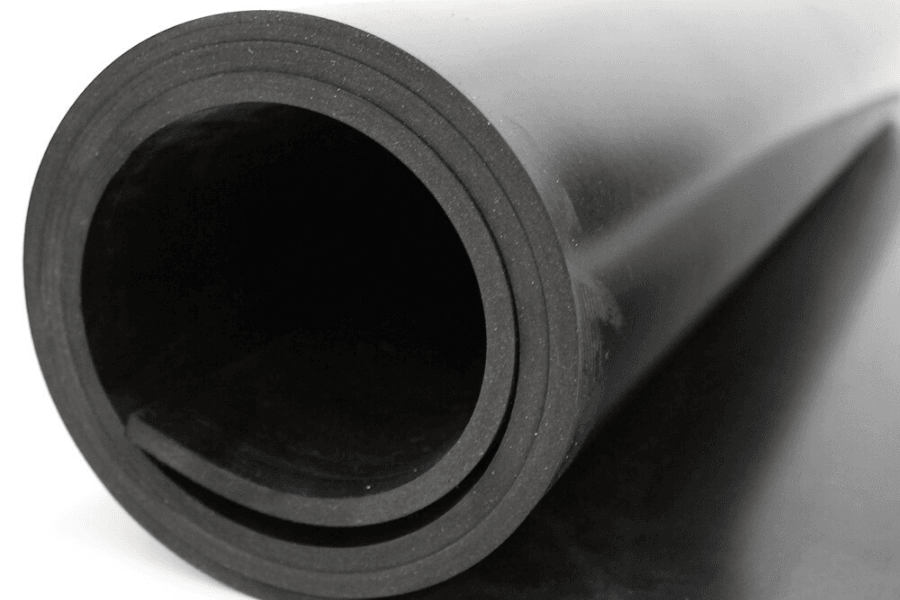

Nitrile rubber sheet black 0 8mm thick x 1200mm wide 60 duro per metre 0 8mm thick premium grade nitrile rubber sheeting.

Nitrile rubber displays good general resistance to oil together with good mechanical properties especially tensile strength compression set flexing and impermeability to gases.

Nitrile rubber sheet is manufactured from a copolymer of butadiene and acrylonitrile with excellent mechanical properties.

This is due to nitrile s compatibility with most environments as well as it s relative cost compared to other rubber materials.

Nbr is used in the automotive and aeronautical industry to make fuel and oil handling hoses seals grommets.

Nitrile rubber also known as nbr buna n and acrylonitrile butadiene rubber is a synthetic rubber derived from acrylonitrile acn and butadiene.

Mykin s rn00170 nitrile buna n 70 durometer is a general purpose copolymer of butadiene and acrylonitrile.

Comparing with neoprene rubber sheets this one also has the characteristic of chemical resistance but it is not suitable for applications in contact with antioxidant agents and chlorine.

The main commercial nitrile rubber sheet properties include a hardness of 70 and a temperature range between 15 c and 90 c.